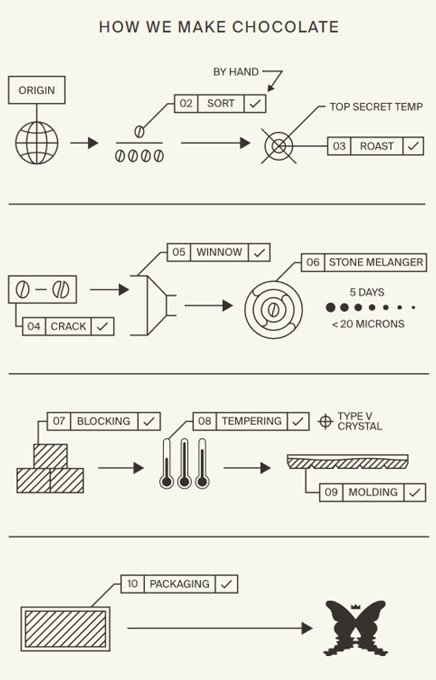

How We Make Chocolate

Origin. First, we find a cacao farm using ethical farming methods. We absolutely do not support any farms using slave labor or child slave labor. Our wholesalers know how important this is to us, and we work together to make sure every farm we buy from is Fair Trade Certified. The cacao beans are fermented and dried before arriving in the United States. Each farm or coop has their own fermenting style, depending on what’s available in each region.

2. Sort. We hand sort the cacao beans to remove any cut, withered, moldy, or flat beans.

3. Roast. Roasting the cacao beans is a tricky process. We tend to like a light to medium roast in general. But the beans tell us where the sweet spot is for each different region. The taste of the chocolate can be very different depending on the roast. We have a very specific roasting profile for each bean. (We deliberately changed the name from cacao beans (raw) to cocoa beans (roasted).)

4. Crack. After roasting and cooling, we crack the cocoa beans. We hand feed the cocoa beans through the cracker. This takes about an hour for 20 lbs of cocoa beans.

5. Winnow. We take the cracked cocoa nibs and shells mixed together and separate them through winnowing. At the end of the each wind tunnel, there are cocoa shells at one end and cocoa nibs in the other. We hand feed the mixture into the wind tunnels, and it takes about 3 hours to feed 20 pounds through the system.

6. Stone Melanger. The cocoa nibs get slowly fed into a stone melanger and run for roughly 5 days to get to 20 microns or less. This is where chocolate gets it’s smooth mouth feel. If you taste and feel grittiness in your chocolate, it is probably through the melanger process. We test every batch of chocolate to make sure it is less then 20 microns. One great thing about stone melangers is the main contact with the chocolate is granite stone, not metal. We also conch our chocolate during this phase. Sugar or other ingredients are added during this part of the process. (Milk powder for milk chocolate; coffee for coffee chocolate, etc.)

7. Blocking. After we’ve tested for less then 20 microns, we pour the melted chocolate into blocks or straight into our tempering machine.

8. Tempering. Another tricky part of working with chocolate. Tempering chocolate means we want the chocolate in a Type V crystal structure. This keeps the cocoa butter and fiber intertwined in such a way that keeps the chocolate shiny, and it has a good snap when you bite into it. If you’ve ever gotten chocolate with a white film on it, it’s just out of temper (not in the Type V crystal structure anymore.) It’s still edible, but might not have that shine to it, or a nice snap when bitten. Really out-of-temper chocolate might even taste chalky, because the cocoa butter has separated from the fiber. Type V crystal structured chocolate usually lasts about a year when chocolate has been kept between 55 degrees and 75 degrees.

9. Molding. Immediately after getting the chocolate at the exact right temperature (temper), we mold. We pour the chocolate into bar molds and put them into the fridge for 20 minutes to set the temper quickly. (It has to sit for 4 hours in room temperature to set.) When we do a large batch, we can do 160 bars. But we usually hand temper and mold about 20-30 bars at a time.

10. Packaging. We hand package each bar or set them into our display cases.